Release Date:2024-07-31 16:18:28 Popularity:

Liquid filling machines are one of the widely used equipment in modern industry, which are used to accurately fill various liquid products into different types of containers. The price of liquid filling machines is affected by multiple factors, such as the type, function, production capacity, brand, etc. of the equipment. This article will discuss in detail the main factors affecting the price of liquid filling machines, as well as the price trend of the current market.

1. Main factors affecting the price of liquid filling machines

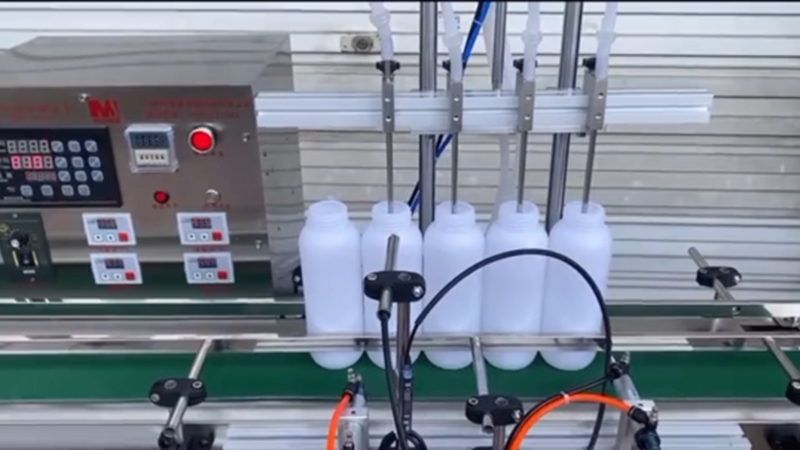

1. Equipment type: There are many types of liquid filling machines, including piston filling machines, flow meter filling machines, rotary filling machines, etc. Different types of filling machines are suitable for different liquid properties and packaging requirements, so the price difference is large. For example, piston filling machines suitable for high-viscosity liquids are usually more expensive due to their complex structure and precise control system.

2. Function and degree of automation: The function and degree of automation of liquid filling machines directly affect the price. The price of basic semi-automatic filling machines is relatively low, while the price of fully automated equipment will be significantly increased due to the integration of multiple functions such as automatic feeding, automatic metering, automatic filling and automatic sealing. In addition, high-end equipment with intelligent control systems, automatic fault detection and remote monitoring functions are more expensive.

3. Production capacity: The production capacity of the liquid filling machine, that is, the number of bottles that can be filled per minute or hour, is also an important factor affecting the price. High-capacity equipment usually requires more advanced technology and more stable structural design to ensure accuracy and reliability under high-speed operation, so the price is higher. Conversely, low-capacity equipment is relatively cheap.

4. Material and manufacturing process: The material and manufacturing process of the liquid filling machine have a direct impact on the durability, stability and hygiene standards of the equipment. For example, stainless steel equipment is not only highly corrosion-resistant, but also easy to clean, and meets the hygiene requirements of the food and pharmaceutical industries, but the cost is higher. In addition, precision manufacturing processes and high-quality parts will also increase the cost of the equipment, thereby pushing up the price.

5. Brand and after-sales service: Liquid filling machines of famous brands are usually more expensive, not only because of the added value of the brand itself, but also because these brands usually provide better technical support, after-sales service and quality assurance. Good after-sales service is essential for the long-term operation of the equipment, including equipment maintenance, parts supply and technical training.

2. Liquid filling machine market price trend

1. Price range: The price range of liquid filling machines is very wide, ranging from several thousand yuan to hundreds of thousands of yuan. Simple manual or semi-automatic filling machines usually cost between several thousand and tens of thousands of yuan, while fully automatic liquid filling machines with rich functions and high automation may cost hundreds of thousands of yuan or even higher. The specific price depends on the combined effect of the above factors.

2. Market demand: With the improvement of various industries' requirements for automated production, the market demand for liquid filling machines continues to grow. The increasing demand for efficient and precise filling in industries such as food and beverage, pharmaceutical chemicals, and daily chemicals has driven the market share of high-end liquid filling machines. This type of equipment is not only expensive, but also has fierce market competition. Technical content and after-sales service have become the key to brand competition.

3. Technological development: With the advancement of science and technology, the technical content of liquid filling machines has been continuously improved, and the intelligence and automation level of equipment has been continuously improved. Intelligent equipment can realize functions such as remote monitoring, automatic adjustment, and data analysis, providing enterprises with more efficient production solutions. Although the introduction of these technologies has increased the cost of equipment, it has also improved production efficiency and product quality, so it has become more and more popular in the market.

4. Imported vs. domestic: Imported liquid filling machines are usually more expensive, mainly due to their brand effect and advanced technology. However, with the improvement of domestic equipment manufacturing level, domestic liquid filling machines have competitive advantages in cost performance, especially in the small and medium-sized enterprise market. Domestic equipment is increasingly improved in terms of technical performance, price and after-sales service, and gradually won the trust of more users.

3. How to choose a suitable liquid filling machine

When purchasing a liquid filling machine, enterprises should choose suitable equipment according to their own production needs, budget and product characteristics. The following suggestions are for reference:

1. Clarify production needs: Determine the type and specifications of the equipment according to the type, viscosity, output, etc. of the product.

2. Pay attention to equipment quality and brand: Choose a brand with reliable quality and perfect after-sales service to ensure the long-term stable operation of the equipment.

3. Consider cost performance: On the premise of meeting production needs, choose equipment with high cost performance to avoid over-investment.

4. Technical support and after-sales service: Choose a supplier that provides perfect technical support and after-sales service to ensure daily maintenance of the equipment and emergency fault handling.

In summary, the price of liquid filling machines is affected by many factors, and different market demands and technological development trends are also constantly changing. When choosing, enterprises should comprehensively consider factors such as the function, quality, and after-sales service of the equipment to ensure efficient and long-term returns on investment.