Release Date:2024-07-17 19:06:13 Popularity:

With the continuous development of the medical and health industry and the global emphasis on public health safety, the demand for swabs has increased dramatically. In order to improve production efficiency and product quality, automatic swab packaging machines came into being. This advanced equipment not only greatly improves the packaging speed of swabs, but also shows significant advantages in ensuring a sterile environment, reducing labor costs and improving packaging consistency.

1. Definition and working principle of automatic swab packaging machine

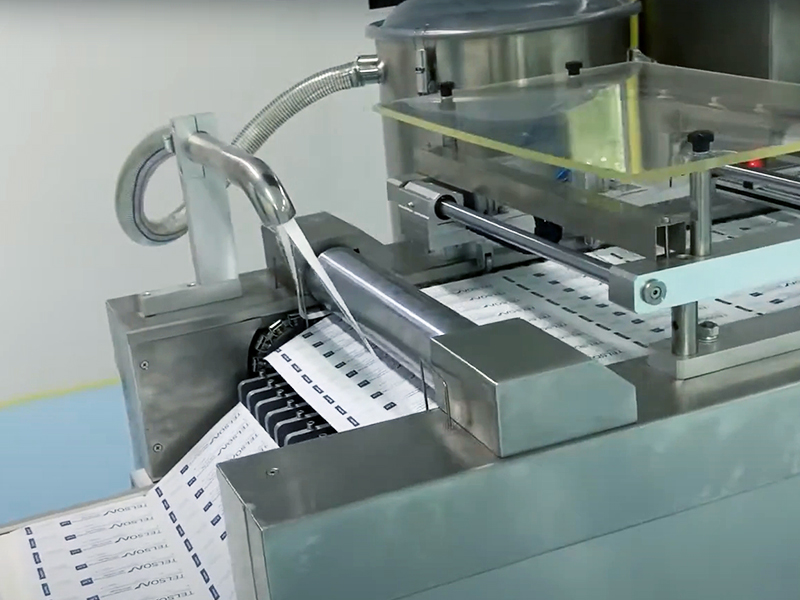

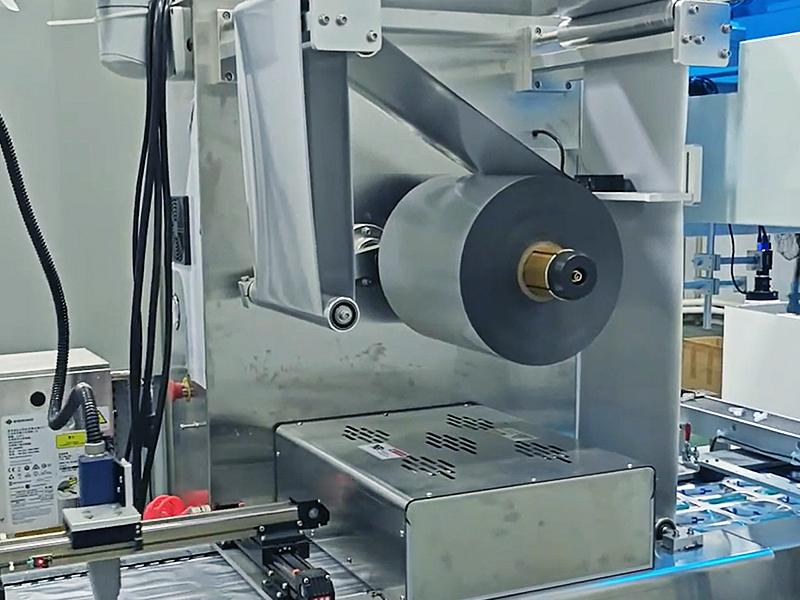

The automatic swab packaging machine is a device specially used for automatic packaging of swab products. It can automatically complete a series of operations such as feeding, sorting, packaging, and sealing of swabs. Through high-precision sensors and intelligent control systems, the swab automatic packaging machine ensures the efficiency and hygiene of the entire packaging process.

Its working principle mainly includes the following steps:

1. Feeding: The swabs automatically enter the packaging machine through the feeding system. The system can identify and arrange the swabs to ensure that each swab is in place accurately.

2. Sorting: The automatic swab packaging machine is equipped with a high-precision sorting device, which can sort swabs according to preset packaging specifications.

3. Packaging: The sorted swabs are sent to the packaging area, and the swabs are placed into the packaging bag through a robotic arm.

4. Sealing: The packaging bag is sealed by heat sealing or other sealing methods to ensure the sealing and sterility of the packaging.

5. Detection and output: After packaging is completed, the automatic packaging machine performs quality inspection through the detection device. Qualified products are transported to the output area, and unqualified products are rejected.

2. Advantages of swab automatic packaging machine

1. Efficiency: The automatic swab packaging machine can realize continuous and large-volume packaging operations, greatly improving production efficiency. Compared with traditional manual packaging methods, automatic packaging machines are faster and can meet the huge market demand for swab products.

2. Packaging quality consistency: The automatic swab packaging machine ensures consistent packaging quality of each swab through a sophisticated control system and high-precision sensors, reducing quality differences caused by human factors.

3. Sterility: Medical swabs have extremely high sterility requirements. The automatic swab packaging machine operates in a sterile environment, avoiding manual contact and contamination, and ensuring the hygiene and safety of the product.

4. Reduce labor costs: Automatic packaging machines reduce reliance on labor and reduce the company's labor costs. At the same time, the labor intensity of workers is reduced and the safety of the working environment is improved.

5. Intelligent management: Automatic swab packaging machines are usually equipped with intelligent control systems that can monitor the production process in real time, detect and handle abnormal situations in a timely manner, and improve the stability and reliability of production.

3. Application fields of swab automatic packaging machine

Swab automatic packaging machines are widely used in the medical and health industry, especially in the fields of new coronavirus detection, influenza detection, bacterial culture and other fields.

1. New coronavirus testing: During the epidemic, the demand for virus testing swabs surged. The automatic swab packaging machine can efficiently produce and package large quantities of testing swabs to ensure the smooth progress of epidemic prevention work.

2. Influenza testing: During the flu season, testing swabs are also in high demand. The automatic swab packaging machine helps manufacturers quickly respond to market demand and provide sufficient testing swabs.

3. Bacterial culture: In the laboratory, bacterial culture swabs are also commonly used consumables. The automatic packaging machine ensures sterile packaging of swabs and prevents experimental results from being affected by contamination.

4. Development Trend of Automatic Swab Packaging Machine

With the advancement of science and technology and changes in market demand, automatic swab packaging machines are developing in the direction of intelligence, environmental protection, and multi-functionality.

1. Intelligentization: In the future, automatic swab packaging machines will make greater use of technologies such as the Internet of Things, big data, and artificial intelligence to achieve more intelligent production management and quality control. Through data analysis and machine learning, the equipment can automatically optimize the packaging process and improve production efficiency and product quality.

2. Environmental protection: The increasing awareness of environmental protection promotes the development of automatic swab packaging machines towards green development. Use more environmentally friendly materials and energy-saving technologies to reduce packaging material waste and environmental impact.

3. Multifunctionality: The automatic swab packaging machine will have more functions, such as automatic label printing, automatic labeling, automatic detection, etc., to meet the diverse needs of different products and markets.

In summary, as an important equipment in the medical and health industry, the automatic swab packaging machine is promoting the modernization and automation of the production and packaging of swab products with its advantages of high efficiency, high quality, and intelligence. In the future, with the continuous innovation and application of technology, automatic swab packaging machines will bring more opportunities and challenges to the medical and health industry and promote the high-quality development of the industry.