Release Date:2024-06-22 20:07:44 Popularity:

With the advancement of science and technology and the changes in market demand, the manufacturing and packaging industries are constantly seeking new solutions to improve production efficiency, ensure product quality and reduce production costs. The emergence of automated weighing and packaging equipment just meets this demand. As an indispensable and important part of the modern production line, automated weighing and packaging equipment is gradually replacing traditional manual weighing and packaging methods with its high efficiency, precision and reliability, and has become an important tool for enterprises to enhance their competitiveness. This article will explore in depth the advantages of automated weighing and packaging equipment and its important applications in various industries.

Definition of automated weighing and packaging equipment

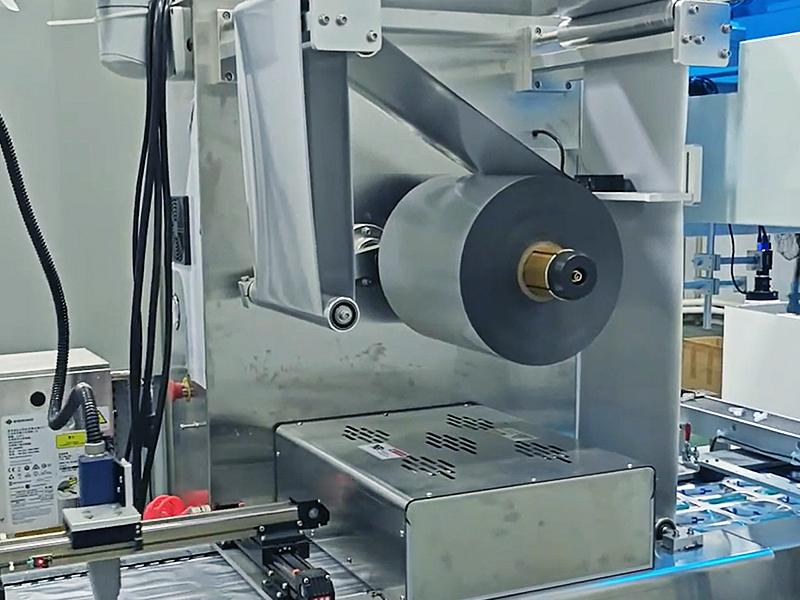

Automated weighing and packaging equipment refers to automated mechanical equipment that integrates multiple functions such as weighing, packaging and sealing. Through advanced sensors, control systems and mechanical structures, the equipment can realize a series of operations from automatic weighing of materials, automatic bagging to automatic sealing. Its main features are high efficiency, precision and stability, and it is widely used in food, medicine, chemical industry, agriculture and other industries.

Main advantages of automated weighing and packaging equipment

1. Improve production efficiency: Automated weighing and packaging equipment can complete the weighing and packaging of a large amount of materials in a short time, greatly improving production efficiency. Traditional manual weighing and packaging requires a lot of manpower and time, while automated equipment can operate continuously and at high speed, significantly shortening the production cycle and meeting the needs of mass production. For example, an efficient automated weighing and packaging equipment can complete dozens of weighing and packaging operations in one minute, greatly improving production capacity.

2. Improve weighing accuracy: Weighing accuracy is an important indicator of packaging quality. Automated weighing and packaging equipment is equipped with high-precision sensors and advanced control systems, which can accurately weigh materials to ensure that the weight of each package is within the set range. The automatic calibration function of the equipment can also be adjusted as needed to further improve the accuracy and consistency of weighing, reduce human errors, and ensure the stability of product quality.

3. Reduce production costs: Although the initial investment of automated weighing and packaging equipment is high, its efficient production capacity and low labor costs significantly reduce the overall production cost. The equipment can operate continuously, reducing dependence on manual labor, labor costs and management costs. At the same time, high-precision weighing and packaging functions reduce the waste of raw materials and improve the economic benefits of production. For example, in the food industry, accurate weighing can avoid excess filling, thereby saving a lot of raw material costs.

4. Improve operational safety: The use of automated weighing and packaging equipment reduces the frequency and intensity of manual operation and reduces the risk of safety accidents that may occur during operation. The equipment is usually equipped with a variety of safety protection devices, such as safety doors, emergency stop buttons, photoelectric protection, etc., to ensure the safety of operators. In addition, the automated operation of the equipment also reduces the labor intensity of workers and improves the safety and comfort of the working environment.

5. Enhance production flexibility: Modern automated weighing and packaging equipment has strong flexibility and can be quickly adjusted and switched according to the packaging needs of different products. By replacing molds and adjusting parameters, the equipment can adapt to the packaging needs of products of various specifications and shapes, meet the diversified needs of the market, and improve the market competitiveness of enterprises. For example, in the chemical industry, the packaging specifications of different products may vary, and automated equipment can be quickly adjusted to meet different packaging needs.

6. Data monitoring and management: Modern automated weighing and packaging equipment is usually equipped with a data acquisition and monitoring system that can monitor, record and analyze various data in the packaging process in real time. Enterprises can use these data to monitor and optimize the production process, discover and solve problems in a timely manner, and improve production efficiency and product quality. At the same time, the accumulation and analysis of data can also provide a scientific basis for the production decision-making of enterprises and promote the intelligent management of enterprises.

Automated weighing and packaging equipment is widely used in various industries. The following are some of the main application areas:

1. Food industry: Automated weighing and packaging equipment is used for weighing and packaging of various foods, such as rice, flour, candy, nuts, seasonings, etc., to ensure the weight and packaging quality of the products.

2. Pharmaceutical industry: In the pharmaceutical industry, automated equipment is used for weighing and packaging of medicines and health products to ensure the accuracy of each dose and improve the safety and effectiveness of medicines.

3. Chemical industry: Chemical products have high requirements for weighing and packaging. Automated equipment can meet the weighing and packaging needs of various chemical raw materials and finished products, and improve production efficiency and product quality.

4. Agricultural field: In the agricultural field, automated weighing and packaging equipment is used for weighing and packaging of seeds, fertilizers, feed, etc. to ensure the packaging quality and weight consistency of products.

5. Electronics industry: In the production process of electronic products, there are strict requirements for weighing and packaging of precision parts. Automated equipment can achieve high-precision weighing and packaging operations.

The development direction of automated weighing and packaging equipment

1. Intelligence and digitalization: With the development of Industry 4.0, automated weighing and packaging equipment will become more intelligent and digital. By introducing the Internet of Things (IoT) and artificial intelligence (AI) technology, the equipment can achieve intelligent monitoring, predictive maintenance and production optimization, and improve the intelligence level of the equipment.

2. Modular design: The future automated weighing and packaging equipment will be more modular, and can be quickly adjusted and upgraded according to different production needs, improving the flexibility and production efficiency of the equipment.

3. Environmental protection and energy saving: Environmental protection and energy saving will become an important direction for the development of automated weighing and packaging equipment in the future. The equipment will adopt more environmentally friendly materials and energy-saving technologies to reduce energy consumption and environmental pollution, and promote the development of green manufacturing.

4. High precision and high speed: With the increasing market demand for high quality and high efficiency, automated weighing and packaging equipment will develop in the direction of higher precision and higher speed, improving production efficiency and product quality.

5. Human-machine collaboration and safety: Human-machine collaborative robots will be widely used in automated weighing and packaging equipment. Combined with artificial intelligence and sensing technology, human-machine collaborative equipment will achieve more efficient and safer production operations, improve production efficiency and the safety of the working environment.

Automated weighing and packaging equipment is leading the development trend of modern industrial packaging with its high efficiency, precision and reliability. It has significant advantages in improving production efficiency, improving weighing accuracy, reducing production costs, improving operational safety, enhancing production flexibility and data monitoring and management, and has become an important means for enterprises to enhance their market competitiveness. With the continuous advancement of technologies such as intelligence, digitization, modularization, environmental protection and human-machine collaboration, automated weighing and packaging equipment will continue to develop and bring greater economic benefits and market competitiveness to enterprises. In the future, automated weighing and packaging equipment will continue to play its important role and promote various industries to move towards efficient, intelligent and sustainable development.