Release Date:2024-06-20 23:47:50 Popularity:

With the development of the global economy and the changing market demand, the packaging industry is facing more and more challenges. In order to meet consumers' demand for high quality and high efficiency, labeling automation equipment, as a representative of modern packaging technology, is rapidly becoming popular and becoming an important driving force for the development of the industry. This article will deeply explore the types, advantages, application fields and future development directions of labeling automation equipment, and reveal its important role in the packaging industry.

Labeling automation equipment can be divided into the following main types according to its functions and application scenarios:

1. Flat labeling machine: used for surface labeling of flat objects, such as cartons, plastic film packaging, etc. Suitable for labeling of various products.

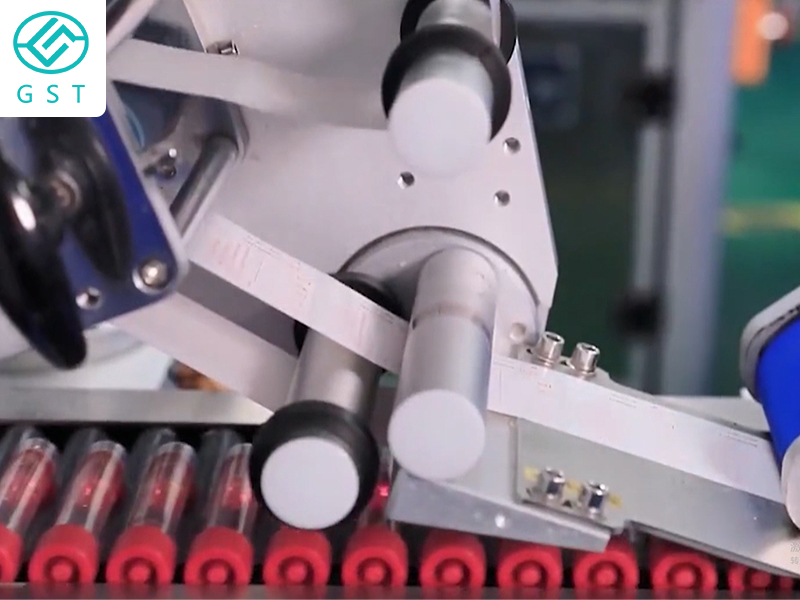

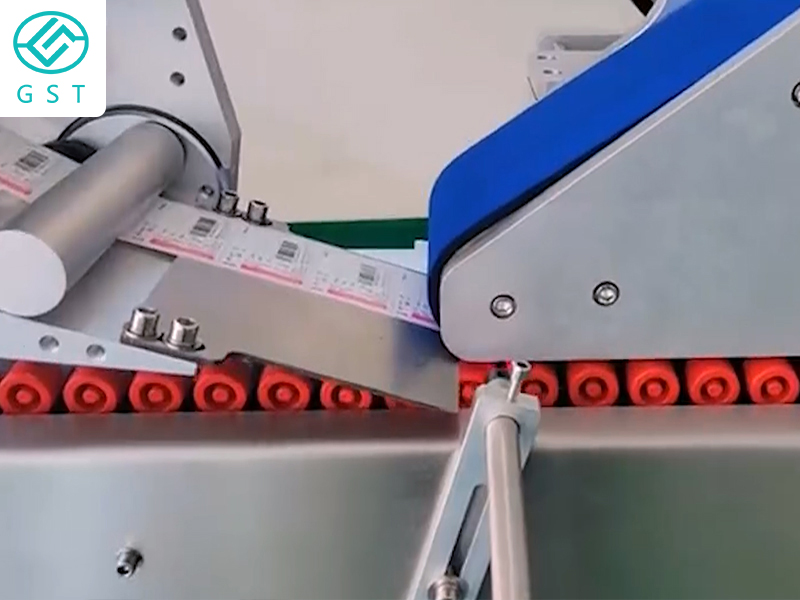

2. Round bottle labeling machine: specially used for labeling of cylindrical objects, such as bottles, cans, etc. Widely used in beverage, food, medicine and other industries.

3. Double-sided labeling machine: can label on two opposite sides of the object at the same time, improve labeling efficiency, and is often used for objects in the shape of flat bottles, square bottles, etc.

4. Side labeling machine: used for labeling on the side of the object, suitable for labeling of various boxes and bagged products.

5. Sealing labeling machine: Labels are pasted while sealing, suitable for products such as medicines and foods that require sealed packaging.

Advantages of labeling automation equipment

1. Improve production efficiency: Automated equipment can complete the labeling process continuously and at high speed. Compared with traditional manual labeling, the production efficiency is significantly improved to meet the needs of mass production.

2. Ensure label accuracy: Automated equipment uses a precision control system to ensure that the label is pasted accurately, avoid position deviations in manual operations, and improve product appearance quality.

3. Reduce labor costs: Although the initial investment in automated equipment is high, its high efficiency and low labor costs in operation significantly reduce the overall production cost.

4. Improve product consistency: Automated equipment can ensure the consistent quality of label pasting for each product, improve the standardization and market competitiveness of the product.

5. Enhance operational safety: Automated equipment reduces the frequency and intensity of manual operations, reduces the risk of safety accidents that may occur during operations, and ensures the safety of workers.

Labeling automation equipment is widely used in various industries, and its main application areas include:

1. Food and Beverage: In the food and beverage industry, labeling automation equipment is used for labeling of bottled and canned products to ensure the neatness and beauty of labels and improve the market appeal of products.

2. Medicine and Health Care: The pharmaceutical industry has extremely high requirements for the accuracy of label information. The application of automatic labeling equipment on packaging such as medicine bottles and boxes ensures the clarity and accuracy of label information and meets industry standards.

3. Cosmetics and Daily Chemicals: The packaging of cosmetics and daily chemical products has high requirements for appearance. Labeling automation equipment helps companies achieve high-quality labeling and improve the grade and brand image of products.

4. Electronic Products: A large number of labels, such as barcodes, production information, etc., need to be pasted on the packaging of electronic products. Labeling automation equipment can complete these tasks quickly and efficiently, and improve production efficiency.

5. Logistics and Warehousing: In the logistics and warehousing industry, labeling automation equipment is used for labeling of various packaging boxes and pallets to ensure the accuracy and clarity of logistics information and improve the efficiency of warehousing and transportation.

The development direction of labeling automation equipment

1. Intelligence and digitalization: The future labeling automation equipment will be more intelligent and digital. By introducing the Internet of Things (IoT) technology, the equipment can achieve real-time monitoring and remote control, and improve the intelligence level of the equipment.

2. Flexibility and modularization: One of the future development trends is the flexible and modular design of the equipment, so that it can quickly adapt to the needs of different products and labels, and meet the needs of multi-variety and small-batch production.

3. Environmental protection and energy saving: Environmental protection and energy saving are important development directions in the future. Labeling automation equipment will adopt more environmentally friendly materials and energy-saving technologies to reduce energy consumption and environmental pollution, and promote the development of green manufacturing.

4. High precision and high speed: With the increasing market demand for high quality and high efficiency, labeling automation equipment will develop in the direction of higher precision and higher speed, improving production efficiency and product quality.

5. Human-machine collaboration and safety: Human-machine collaborative robots (Cobots) will be widely used in the labeling field. Through intelligent sensors and control systems, the equipment will ensure the safety of the human-machine collaboration process and improve the flexibility and safety of the production process.

As an important part of modern packaging technology, labeling automation equipment is gradually changing the production mode of the packaging industry. Its high efficiency, high precision and high quality make it widely used in all walks of life. With the continuous advancement of technologies such as intelligence, digitization, flexibility, environmental protection and energy saving, labeling automation equipment will continue to lead the development trend of the industry and promote the packaging industry to move towards high efficiency, intelligence and sustainable development.

By introducing and optimizing labeling automation equipment, enterprises can not only improve their own production efficiency and product quality, but also better meet market demand and achieve sustainable development. In the future, labeling automation equipment will continue to play its important role and become an indispensable intelligent assistant in the packaging industry.