Release Date:2024-06-14 11:46:36 Popularity:

As a landmark achievement of modern manufacturing, fully automated production lines represent efficient production, intelligent manufacturing and precise control in the Industry 4.0 era. It not only improves production efficiency and product quality, but also significantly reduces production costs and labor intensity. This article will deeply explore the working principle, main features, advantages and application of fully automated production lines in various industries, and look forward to its future development trends.

The working principle of a fully automated production line. A fully automated production line integrates a variety of automation equipment and technologies to realize full-process automation from raw material processing to finished product output. Its basic workflow includes:

1. Raw material supply: Raw materials are transported to various stations of the production line through automatic feeding systems (such as conveyor belts, vibrating feeders, etc.).

2. Production and processing: Each station is equipped with automated processing equipment (such as CNC machine tools, robots, etc.) to process and assemble raw materials according to the preset process flow.

3. Quality inspection: During the production process, real-time quality inspection is carried out through sensors, vision systems, etc. to ensure that products meet quality standards.

4. Product transfer: semi-finished products are transferred from one station to the next through automatic transmission systems (such as robotic arms, conveyor belts, etc.).

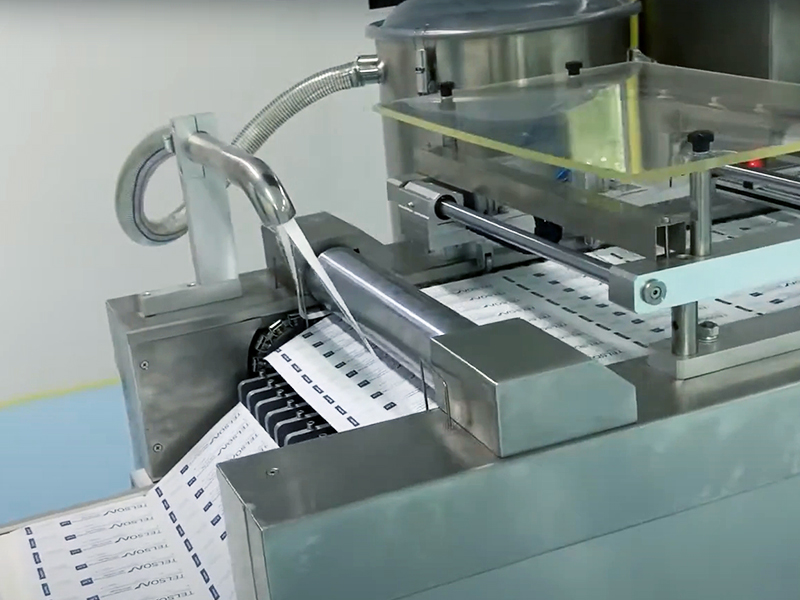

5. Packaging and finished product output: The processed products enter the automatic packaging equipment for packaging, and the finished product is finally output through the conveyor belt.

The main features of fully automated production lines

1. Highly integrated: The fully automated production line integrates multiple links such as automatic feeding, processing, testing, transfer, and packaging, realizing full-process automation of production.

2. High efficiency: The equipment can carry out production operations continuously and at high speed, greatly improving production efficiency and shortening the production cycle.

3. Intelligent: Equipped with advanced control system and human-machine interface (HMI), operators can complete parameter settings and operations through the touch screen, and monitor the operating status of the production line in real time.

4. High precision: Automated equipment and precise control systems ensure the consistency of processing accuracy and product quality.

5. Flexibility: Able to quickly adjust the production line layout and process flow according to production needs to adapt to diverse production tasks.

Advantages of fully automated production lines

1. Improve production efficiency: Fully automated operation significantly increases production speed, reduces manual intervention and waiting time, and greatly improves production efficiency.

2. Ensure product quality: High-precision processing equipment and quality inspection systems ensure the consistency and high quality of each product, reducing the defective rate.

3. Reduce production costs: By reducing labor costs and material waste, fully automated production lines help companies effectively reduce production costs and improve economic benefits.

4. Improve safety and hygiene: The equipment design complies with industry hygiene and safety standards, reducing the chance of manual contact with products and reducing pollution and safety hazards.

5. Enhance market competitiveness: Efficient and precise production capabilities improve the consistency and aesthetics of products, and enhance the competitiveness of corporate products in the market.

Application fields of fully automated production lines

1. Automobile manufacturing: In the automobile manufacturing industry, fully automated production lines are widely used in the processing of automobile parts and vehicle assembly. Its efficient production capacity and strict quality control ensure the safety and reliability of automotive products.

2. Electronic products: The production of electronic products requires extremely high precision and efficiency. Fully automated production lines can meet the production needs of mobile phones, computers, home appliances and other products, ensuring product consistency and high quality.

3. Food and Beverage: The food and beverage industry has extremely high requirements for hygiene and safety. Fully automated production lines can achieve aseptic processing and packaging to ensure food safety and quality.

4. Pharmaceutical industry: The pharmaceutical industry has strict requirements on production environment and product quality. Fully automated production lines can meet the production needs of drugs, medical devices and other products, ensuring the safety and effectiveness of drugs.

5. Chemical industry: In the chemical industry, fully automated production lines are used for the production and packaging of chemicals to ensure accurate measurement and safe handling of materials.

The development trend of fully automated production lines

1. Intelligent manufacturing: In the future, fully automated production lines will further develop in the direction of intelligent manufacturing. By integrating Internet of Things (IoT) technology and big data analysis, equipment can achieve remote monitoring, predictive maintenance and production optimization, improving production efficiency and equipment utilization.

2. Flexible production: In order to meet the market's demand for customization and small batch production, fully automated production lines will develop in a flexible direction. Equipment will have greater adaptability and can quickly adjust to the needs of different products and production processes.

3. Green manufacturing: With the increasing awareness of environmental protection, fully automated production lines will pay more attention to energy efficiency and the use of environmentally friendly materials. Equipment manufacturers will develop more environmentally friendly and sustainable solutions that reduce environmental impact.

4. Human-machine collaboration: Future production lines will introduce more human-machine collaborative robots, combined with artificial intelligence (AI) technology, to achieve more efficient and safer production operations.

As an important part of modern industrial production, fully automated production lines have significantly improved production efficiency and product quality with their high efficiency, precision, and intelligence. In many fields such as automobile manufacturing, electronic products, food and beverages, medicine, and chemical industry, fully automated production lines have shown broad application prospects. With the continuous advancement of science and technology and changes in market demand, fully automated production lines will continue to play an important role in promoting various industries to move towards efficient, intelligent and sustainable development. By introducing and optimizing fully automated production lines, companies can not only improve their market competitiveness, but also better meet consumer needs and achieve sustainable development.